The circular economy is here to stay and literally turn upside down how we have been doing things. Produce-use-discard is finished. We are speaking of a proposal to which, little by little, we all -governments, corporations and citizens – must advance if we want to ensure our survival and that of the planet. Ambitious, yes, but realistic. And there are more and more companies joining the change.

1. A new sustainable model

The circular economy is an economic model based on the operation of the natural systems. It recovers the awareness of the connection between all the agents of the system and its cyclical operation: no element is wasted, everything is converted into nutrient, food. Thus, the production of circular goods and services maintains the valuable resources in perpetual circulation, so that they are available for the future generations, without need to continue devastating.

The new approach asserts that it is no longer enough to only recycle, but the products and business models must be redesigned and commitment must be made definitively to renewable and clean energy. It aspires to raise the awareness of citizens and economic actors to repair and protect our environment.

The circular economy is, therefore, the paradigm opposite to the linear economic model that has ruled since the Industrial Revolution: produce – use – discard. Little by little, this model that generates waste, is intensive in the consumption of resources and harmful to the environment is changing to that of produce-use-recirculate-produce…

The closing of the cycle of products proposed by the circular economy means great advantages, not only environmental, but also economic and social.

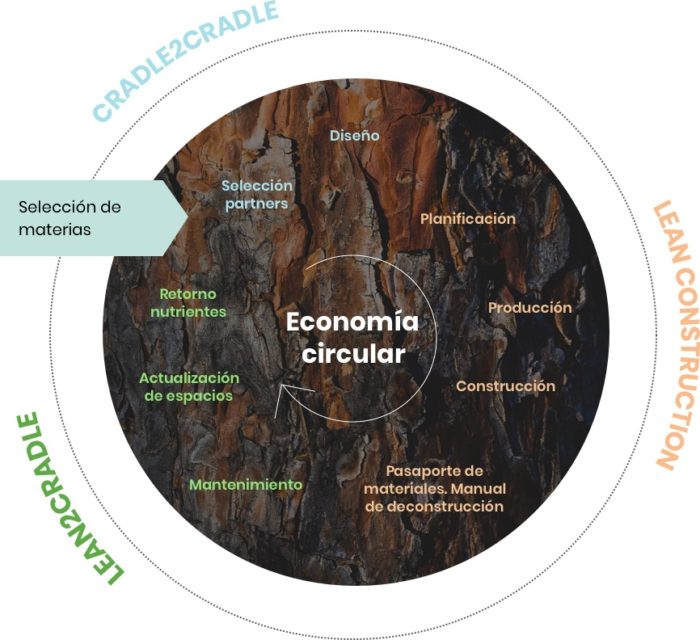

2. This is how the circular economy works

• Circular Design

To ensure the possibility of recovering the materials or elements that comprise a product at the end of each cycle of use, it must have been designed with this objective. That is, the actual concept of the product (materials, design, manufacture, assembly, business model) takes into account the preservation of the value of its components, which must also be healthy and safe.

For example, an electrical appliance manufacturer that applies the principles of the circular economy will select materials (paints, plastics and other finishes) that do not contain toxic substances, it will use mechanical fittings (screws and nuts), a modular design (so that it can be updated easily) and recyclable materials (they can be recycled as raw materials or reutilized as they are). In addition, it will seek a partner to offer, for example, laundry service, instead of selling a washing machine.

When an electrical appliance manufacturer decides on this model, this will allow it to renew its product more easily, by incorporating technological updates more simply. This will all result in better service for its end client.

• Simplify the design

The use of less variety of materials in a product facilitates its recovery, as long as they are not subjected to different finishes. Simplifying the design, it is also possible to know in detail the materials used and ensure that they are healthy and safe in use and in their subsequent recovery.

• Increase the productivity (and the life) of the resources used

This is a maxim of the circular economy: products don’t die (and are not discarded) when the cycle for which they were conceived ends. This connects with what we told you before about designing with future uses in mind. Everything has a second life (and more). The circular economy proposes increasing productivity of the resources used. And this is achieved with the two following aspects.

• Model of cascade

The cycle of use of the material or product is extended to the maximum with the minimum intervention. Cascading management involves the use of hierarchy: re-use, repair, recycle, recirculate.

Let’s imagine, for example, the case of wood, a natural material with great properties for construction. In a cascading model, solid wood represents the product of greatest value. Then would come the plywood made of inferior grade wood that is cut in thin sheets. Then would come the chipboard (or insulation board), that represents the final structural use of wood. And lastly, pellets as fuel for heating. So that this cascade of materials can truly imitate nature, the process must comply with these criteria, among others:

a) Establishing channels for the materials as they connect in cascade. This would include returning the ash from the burnt wood chips to the forests. And defining the time of use so that the best performance and value is obtained at each stage of the cascade.

b) Plan for recovery of product and closure of the cycle.

c) All the chemical products and ingredients used at each stage comply with the appropriate guidelines (there are no problematic chemical products); re-use of materials >65%, and an audit to quantify the use of water.

d) Using renewable energy for 50% of the production (final assembly).

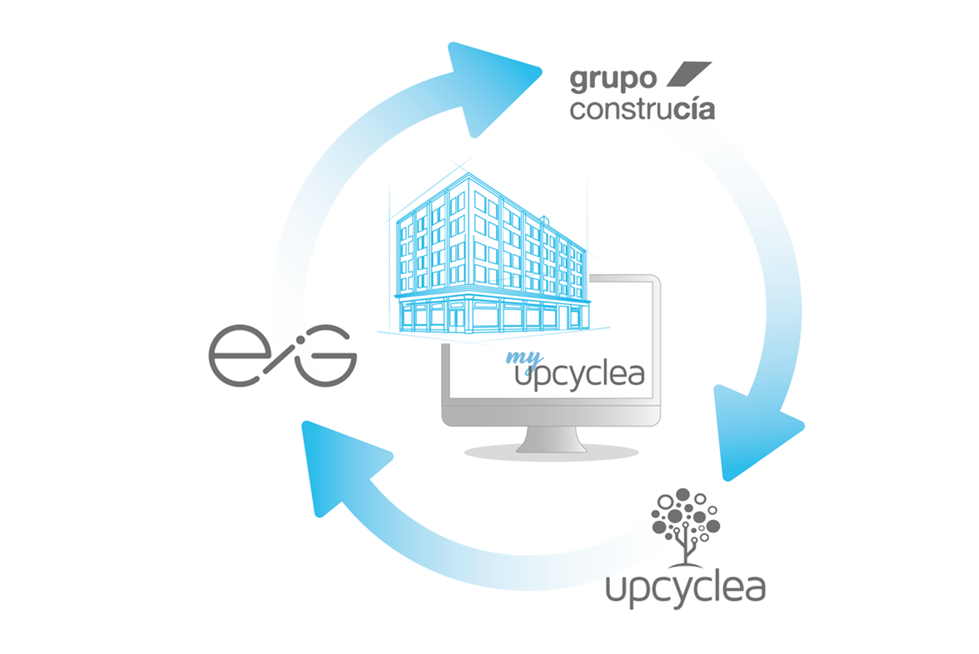

The path is marked and it is up to us to follow it. At Construcía we are firmly committed to an innovative model of circular construction , capable of generating positive impact on the environment and on people.

Click here to see the infographic pdf editable